The Pillow Plate Machine - New generation

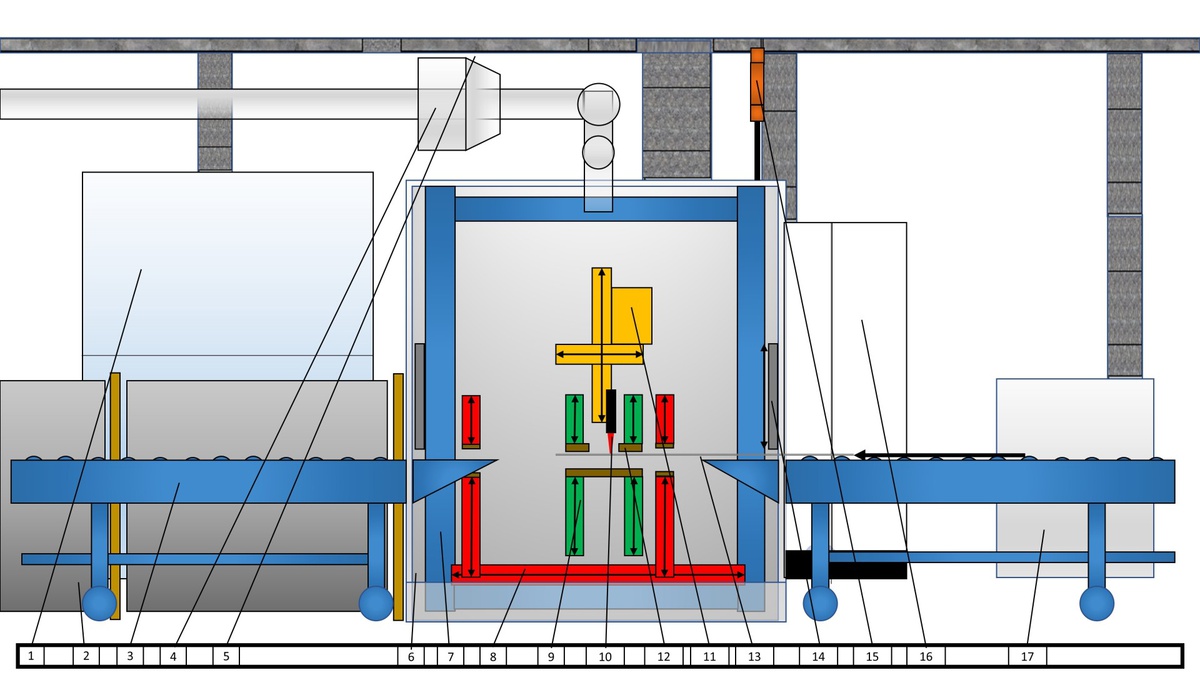

RODOMACH has succeeded in developing a robust new generation for key hole laser welding of Pillow Plates. Underneath you'll find the machines principle with an explanation of the different components.

1. Fibre Laser Trumpf TruDisk

2. Safety fence to protect the operator

3. Input and output table for the plates

4. Extraction installation against flue gases

5. Cable duct for the complete wiring

6. Completely closed steel plate machine guard

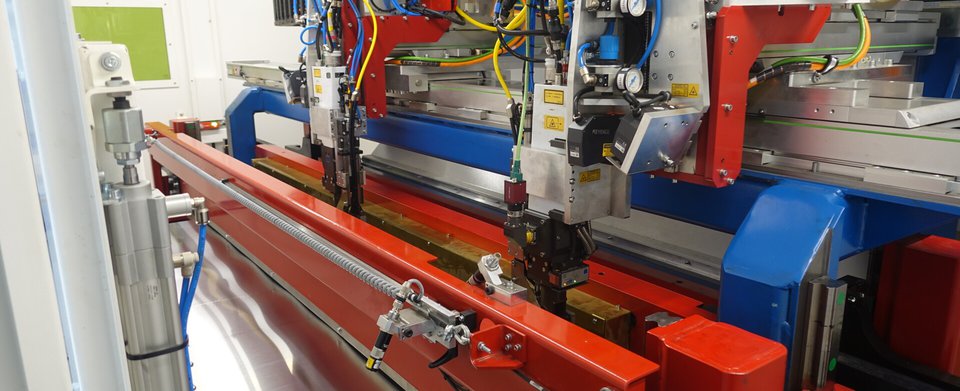

7. Main frame of the welding machine

8. Double servo-controlled transportation system

9. Servo driven clamping beams in the welding zone

10. Special gas head for applying Argon

11. Fast X-Y-Z axis for movement of the welding head

12. Welding beams with segmented, separately spring-loaded blocks

13. Upper and Lower stainless steel sheet metal plate

14. Pneumatic door for the input of the sheet metal plate

15. A signal light for operation on the top of the machine

16. Main cabinet with all required hardware components

17. Cooling unit to cool the sheet metal plates during welding

Product specifications

The machine can be adapted to meet the customers specific requirements. The thickness of the top plate is depending on the used laser power source. Our machine has the following specifications:

| Description | Minimum | Maximum | Unit |

|---|---|---|---|

| Product Length | 600 | 6000+ | [mm] |

| 23.62 | 236.22+ | [Inch] | |

| Product Width | 100 | 2000 | [mm] |

| 25.40 | 78.74 | [Inch] | |

| Plate Thickness Bottom plate | 0.8 | 20 | [mm] |

| 0.03 | 0.31 | [Inch] | |

| Plate Thickness Top plate | 0.8 | 2 | [mm] |

| 0.031 | 0.079 | [Inch] |

Advantages RODOMACH machine

- Servo driven clamping system with fully adjustable clamping force and stroke. (not hydraulic or pneumatic)

- Sophisticated CAD/CAM conversion suitable for one-piece production.

- Automatic focus height adjustment for constant welding quality, for example constant welding depth measurement.

- Cooling bar for a constant welding depth of the complete plate. (plate will not heat up after the first strokes).

- Flow control of shielding gas to ensure a good gas protection of the welding zone.

- Less maintenance and lower operational costs because of the usage of a fibre laser instead of a CO2 laser.

- Production of long plates. Because of the servo driven clamping system and rigid construction for transportation of the plates, our machine is capable of producing plates greater than 16 meters in length.

- When the bottom plate is protected with plastic film, a cooling bar will prevent the film from burning so the film can be removed easily.

- The gas protection head can be cleaned automatically by means of a rotating brush.

- The machine is provided with lighting on the inside.

- To get a good view of the laser area of the machine, a window is placed in 1 door at the operating side, made of specially laminated glass.

- The machine is provided with a tele service feature, allowing remote access and support with short response times.

- With the CAD/CAM software “PillowPlate Creator” provided with the machine, any required shape can be welded or engraved.

- It is possible to prepare the conversion from CAD to CAM on a separate network PC. The converted drawing can then be sent to the machine after which the operator will only have to select the file.

- Use of linear motors with high movement speeds for the X and Y movement of the welding head and produces an extremely rigid and dynamic drive, with a much higher path accuracy than a ball screw. Moreover, this drive does not require maintenance, as no moving rotating parts are used (except the linear guide).

Stitch welding

With this option it is possible to stitch weld the upper plate at the beginning to the bottom plate. After stitch welding the normal welding process will be started. This option will reduce the chance on a gap between top and bottom plate. This can also be important for top plates with complex contours.

Lay-out of the complete machine

CE declaration

The machine will be fully constructed in accordance with CE and will be supplied with operating manual and other required documents.