PillowPlateCreator™

The software which guarantees the shortest and easiest work preparation

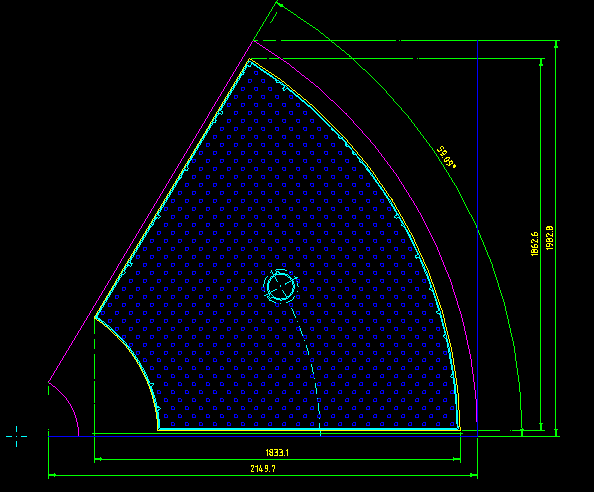

With the CAD/CAM software “PillowPlateCreator” provided with the machine, any required shape can be welded or engraved. An AutoCAD drawing serves as the basis, which must be made with layers in accordance with a defined structure. The translation into a machine file will then take place fully automatically. The advanced CAD post processor will automatically convert a CAD drawing to a laser welding program complying with all requirements imposed on a Pillow Plate. Closing joints, spots, serpentines, texts, rounding off, upslope, downslope and overlap are generated automatically.

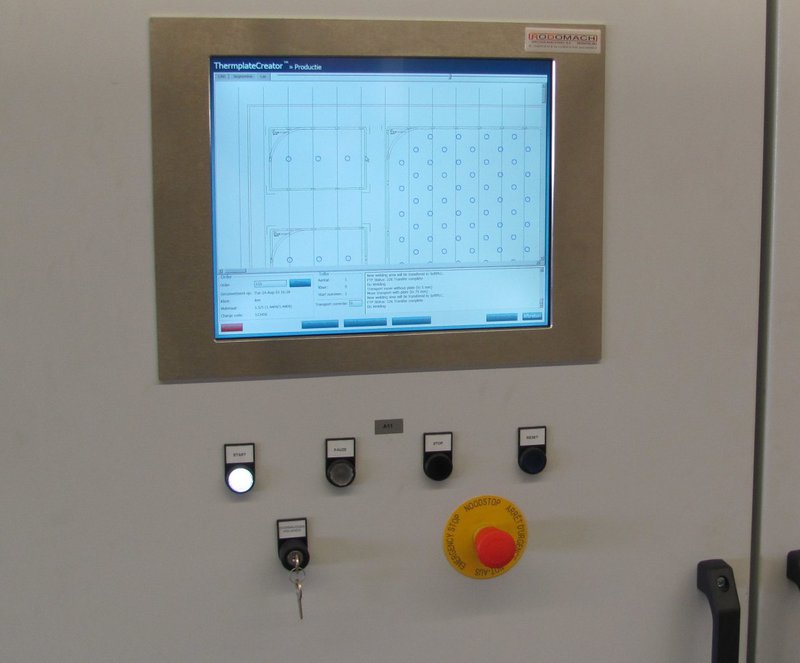

Preparing

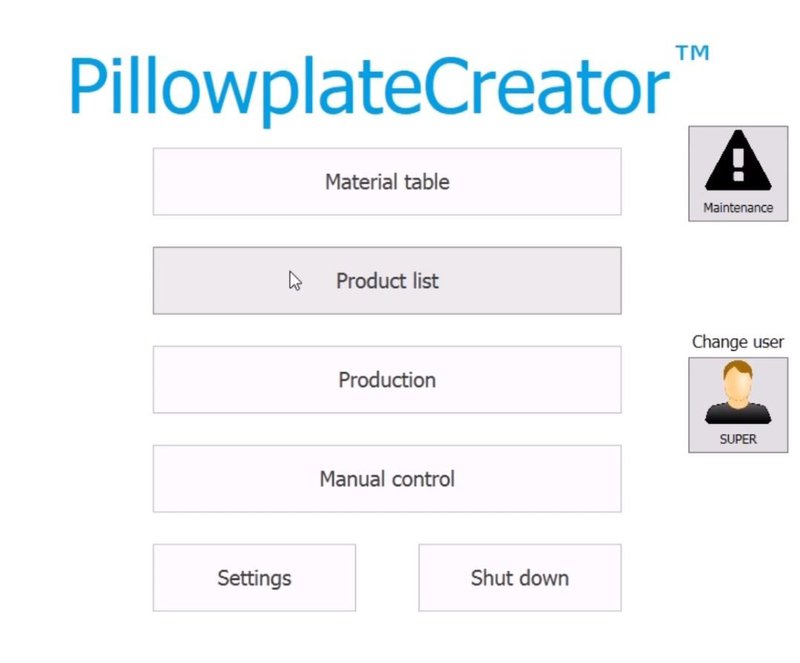

User interface

Preview

RFID Reader with multiple keys

In order to secure the certain operator levels in the software of the machine and you don’t want to use passwords, you can supply each operator with an RFID key. Through different user levels, certain functions and parameters are protected.