Laser Cladding

Laser cladding is used to apply a layer of surface material to workpieces to create a hard, wear-resistant coating layer. The technique is characterized by the low heat input and therefore minimal distortion of components. Laser cladding is a common method in the modern industrial production.

RODOMACH adds value as a system integrator of complete turn-key solutions by offering the laser safety cabinet, laser head handling equipment (robotics), complete automation, the material powder feeder, the water chiller and fume collectors. Each of these components are carefully selected to fit the application requirements and assure a safe and stable operation of the laser equipment. We build laser clad systems all over the world for various applications.

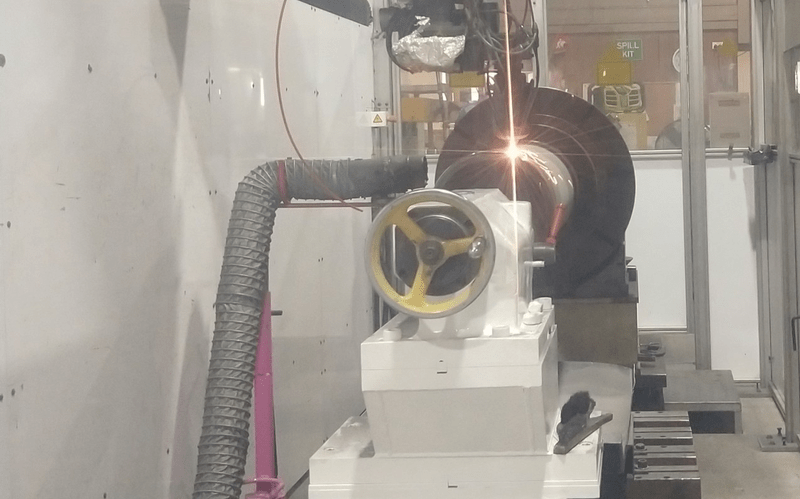

Rodomach has developed a large number of special manipulators for laser cladding such as turntables, lathes, tilting turntable and multi spindle manipulators.

Laser Cladding Cel with tilting turntable