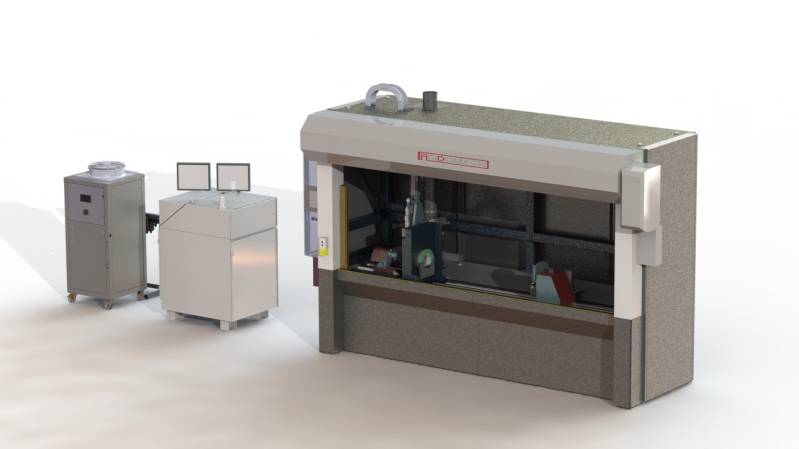

Laser welding End Caps of Towel Radiators

The laser welding installation consists of a loading area for the operator. After loading the individual components and releasing the installation, the welding process begins. The laser optic with gas protection, is mounted on Y-Z servo driven lineair axes which ensures high precision operation and maximum flexibility for all types of manifolds and end caps. The installation is equipped with a laser ource of 2 KW with one optic. The clamping unit at both ends ensures secure positioning of the end cap and manifold during the welding process.

Reliable production process

- Manually feeding of stainless steel manufolds and end caps;

- Optimal integration of different processes (i.e. feeding, clamping, welding, adjusting);

- Online control and service;

- High visual and welding; quality;

- External measuring of laser power;

Maximal flexibility

- Wide range of manifolds geometries (round, square, rectangular, assymetical);

- CAD / CAM environment means easily creating new welding patterns and programs;

- Fast change-over of machine;

- Communication with ERP software (automatical order input).

High levels of quality and safety

- Fiber laser equipment (2KW);

- Controlled proccess for laser welding;

- Dedicated and secure clamping device (incl. gas protection);

- High ergonomic and safety measurements.