Capabilities

RODOMACH realize turnkey projects in Europe for automotive and non-automotive companies. From developing the installation concepts, engineering, assembly up to commissioning and including start up production. Our organization consists of experienced project managers, system engineers, designers and assembly engineers for hardware- and software components, assembly and installation. In close consultation with our customers we look for the best solutions and choose the most suitable hardware and software systems and components, RODOMACH is brand independent and distinguishes itself in the following areas: Arc welding, Resistance welding, Laser welding, Laser cladding, Assembling solution, CNC-machines and positioners.

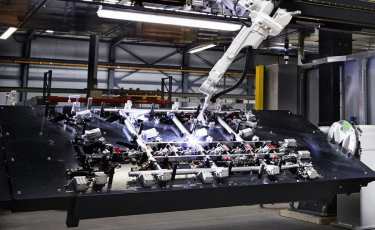

Arc Welding

Arc welding flows through the veins of RODOMACH because of the 15 years' experience with arc welding processes. Arc welding installations can be integrated in standard welding cells and in dedicated machines. A few projects are shown below.

Arc Welding

Assembling Solutions

For System Integration projects RODOMACH takes responsibility for the entire installation, which includes engineering, construction and intelligent linking of various technologies, components and systems. We develop and build our installations with process control and automation that contribute to efficiency.

Assembling Solutions

CNC Fluting Machine

With this combined fluting and grinding machine, customers of Rodomach are able to refurbish rolls for the food and processing industry completely.

Our partner Balaguer Rolls in Spain is our worldwide representative for these machines.

Laser Cladding

Laser cladding is used to add a layer of surface material on a workpieces with to create a hard wear-resistant coating layer. The technique is characterized by the low heat input and therefore minimal distortion of components.

Laser Cladding

Laser Welding

Laser welding is mainly used for joining components that require high welding speeds, thin and small weld seams and low thermal distortion. Laser welding is an excellent automatic operation, very accurate and the quality is controlled online during the process.

Laser Welding

Positioners

RODOMACH has developed special positioners, also called manipulators, for different purposes. Typical situations where these can be used are: Thermal Flame Spraying, Laser Cladding, Fiber reinforced rubber technology and welding process.

Positioners

Resistance Welding

RODOMACH has many years experience with resistance welding processes. Depending on the product geometries and demands we can choose the appropriate resistance welding variants such as spot welding, projection welding and medium frequency (MF) welding.

Resistance Welding

Robot Tracks

RODOMACH developed linear motion tracks for robots for all kind of purposes. As a developer of special machines, Rodomach knows which details are important for you as a customer. We’ve developed linear robot axis for palletising, welding, wrapping, flame spray technology and much more.

Robot Tracks