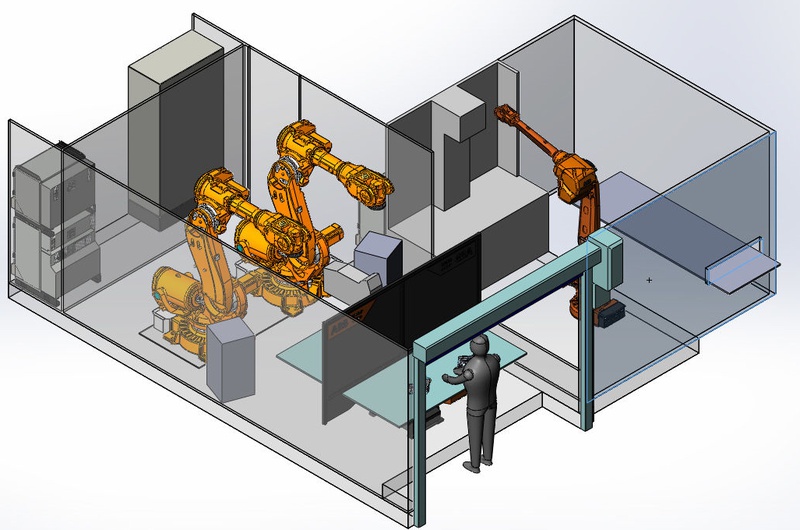

Standard Robot Spot Welding Cell Plus

The standard spot welding cell is developed for a wide range of product dimensions. To ensure process stability and enable easy and secure transport all main components (like robot(s) and turn table are mounted on a stable welded base frame. Depending of the customer requirements and required performance the spot welding cell can be equipped with 1, 2 or 3 robots.

By using the turn table device, with or without auxiliary axes, the operator can load the single parts while the robots are welding. Optionally the spot welding cell can be equipped with an 3rd robot for handling the welded parts from the fixture and transport the welded parts to an unloading conveyor.

High output and reliable production process

- Developed for wide range of product dimensions;

- Optimal integration of standard modules and components;

- Integration of internal logistic process;

- High welding quality.

High flexibility

- Spot welding by robots;

- Turn table with auxiliary axes;

- Fast change-over of fixtures;

- PLC or robot controlled;

- Communication with ERP software.

High levels of quality and safety

- Mounted on a stable welded base frame;

- Monitoring and process control;

- Poka Yoke (failure control);

- High ergonomic and safety measurements;

- Online control and service.